This cronicles the continuing work of Rob Napier on the creation of the Dorade model. The model will represent the yawl as she was when she won the Trans-Atlantic Race in 1931. Our previous blogs about Rob (found here) and the initial stages of his work (found here) last 2012 highlights the process of creating the Dorade model. Image credit is shown on each photo. Captions by Rob Napier.

The basic material for the new model of Dorade is basswood. These 3/8-inch-thick boards, each a scale 1 foot thick on the model, will be used for the layers, or lifts, that form the hull. (Image by Rob Napier)

The basic material for the new model of Dorade is basswood. These 3/8-inch-thick boards, each a scale 1 foot thick on the model, will be used for the layers, or lifts, that form the hull. (Image by Rob Napier)

Here, I am using proportional dividers to transfer a waterline from the plans to a basswood board to make a lift. The waterline is being faired with a batten held in place by spline weights. The scale of the new model is 1:32 (3/8”=1’); the hull will be 19-1/2” long. (Image courtesy Dawn Norris Photography)

Here, I am using proportional dividers to transfer a waterline from the plans to a basswood board to make a lift. The waterline is being faired with a batten held in place by spline weights. The scale of the new model is 1:32 (3/8”=1’); the hull will be 19-1/2” long. (Image courtesy Dawn Norris Photography)

The cockpit sole is not level with the surface of a lift, so the space for the cockpit is being milled from a lift. (Image by Rob Napier)

The cockpit sole is not level with the surface of a lift, so the space for the cockpit is being milled from a lift. (Image by Rob Napier)

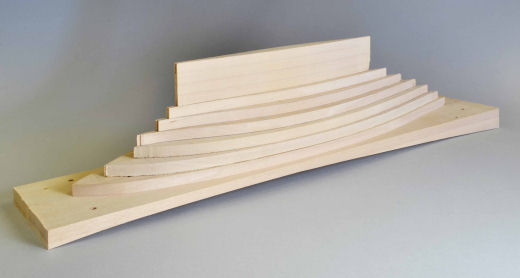

All eleven lifts except the sheer lift (which is lowest in this photo) have been cut to shape, but have not been assembled. The model is built as a pair of half-hulls that will be put together later. This process preserves the centerline plane as an important reference. (Image by Rob Napier)

All eleven lifts except the sheer lift (which is lowest in this photo) have been cut to shape, but have not been assembled. The model is built as a pair of half-hulls that will be put together later. This process preserves the centerline plane as an important reference. (Image by Rob Napier)

The interiors of three lifts have been hollowed to help stabilize the wood and to provide an interior surface for the brass plate that the mounting bolts will attach to. Vertical grooves along the centerline plane are for (from bow to stern) a registration toggle, the two mounting bolts in the keel, the rudder post, and the mizzenmast. There is no groove for the mainmast because it will stand in the hollow. Notches in the sheer lift are for deck structures, and the heavy brass rods are to register the lifts while they are being glued together. (Image by Rob Napier)

The interiors of three lifts have been hollowed to help stabilize the wood and to provide an interior surface for the brass plate that the mounting bolts will attach to. Vertical grooves along the centerline plane are for (from bow to stern) a registration toggle, the two mounting bolts in the keel, the rudder post, and the mizzenmast. There is no groove for the mainmast because it will stand in the hollow. Notches in the sheer lift are for deck structures, and the heavy brass rods are to register the lifts while they are being glued together. (Image by Rob Napier)

The half-hulls have been joined. The hull is mounted on a block, and the block is in the vise. The hull is ready for carving. (Image by Rob Napier)

The half-hulls have been joined. The hull is mounted on a block, and the block is in the vise. The hull is ready for carving. (Image by Rob Napier)

I use simple, traditional hand tools for the majority of wood removal. It is best to work down the entire surface of the hull evenly rather than to finish one area before moving on. (Image courtesy Dawn Norris Photography)

I use simple, traditional hand tools for the majority of wood removal. It is best to work down the entire surface of the hull evenly rather than to finish one area before moving on. (Image courtesy Dawn Norris Photography)

Station and buttock lines are penciled on the developing hull to compare fairness with the plans. This system graphically quickly and easily displays irregularities that need attention. Here, I am fairing the forward part of the keel with a small spoke shave. (Image by Rob Napier)

Station and buttock lines are penciled on the developing hull to compare fairness with the plans. This system graphically quickly and easily displays irregularities that need attention. Here, I am fairing the forward part of the keel with a small spoke shave. (Image by Rob Napier)

Initial shaping and smoothing are complete, but there is still work to do. Of the roughly 870 model hulls I have carved, I can honestly report that Dorade’s faired up noticeably more easily than any other, ever. It is no wonder she is fast through the water. (Image by Rob Napier)

Initial shaping and smoothing are complete, but there is still work to do. Of the roughly 870 model hulls I have carved, I can honestly report that Dorade’s faired up noticeably more easily than any other, ever. It is no wonder she is fast through the water. (Image by Rob Napier)

The carved hull is receiving its first sprayed coat of white primer. This coat is actually a tool to check fairness and will be sacrificed. (Image courtesy Dawn Norris Photography)

The carved hull is receiving its first sprayed coat of white primer. This coat is actually a tool to check fairness and will be sacrificed. (Image courtesy Dawn Norris Photography)

Hull shaping is finished. The groove for the leading edge of the rudder is being hand-carved with a small gouge in the trailing edge of the keel. (Image by Rob Napier)

Hull shaping is finished. The groove for the leading edge of the rudder is being hand-carved with a small gouge in the trailing edge of the keel. (Image by Rob Napier)

Foundation blocks for the deck structures stand in the deck openings. The blocks act as formers for the structures’ vertical surfaces, but will not be part of the finished model. At this point, the top of the model is at the height of the underside of the deck at the side. Bulwarks will be added after the deck is laid. (Image by Rob Napier)

Foundation blocks for the deck structures stand in the deck openings. The blocks act as formers for the structures’ vertical surfaces, but will not be part of the finished model. At this point, the top of the model is at the height of the underside of the deck at the side. Bulwarks will be added after the deck is laid. (Image by Rob Napier)

Deck beams and framing for the deck structures have been installed. Because they will be covered by decking, they are not to scale. They are being faired with a spoke shave. (Image by Rob Napier)

Deck beams and framing for the deck structures have been installed. Because they will be covered by decking, they are not to scale. They are being faired with a spoke shave. (Image by Rob Napier)

The deck framing has been smoothed. With the foundation blocks and mast blanks in place, the model is beginning to look like a boat. (Image courtesy Dawn Norris Photography)

The deck framing has been smoothed. With the foundation blocks and mast blanks in place, the model is beginning to look like a boat. (Image courtesy Dawn Norris Photography)

The cockpit had to be installed and finished before the last deck frames went in. Here I am fitting the port bulkhead of the cockpit. The rudder lies on the building base. (Image courtesy Dawn Norris Photography)

The cockpit had to be installed and finished before the last deck frames went in. Here I am fitting the port bulkhead of the cockpit. The rudder lies on the building base. (Image courtesy Dawn Norris Photography)

The cockpit is finished with scuppers and the brass fitting for the top of the rudder post. The king plank and margin strakes are pear wood. In the opening for the main deckhouse, the top of one mounting bolt can be seen. It is secured to a heavy brass plate inside the model. (Image by Rob Napier)

The cockpit is finished with scuppers and the brass fitting for the top of the rudder post. The king plank and margin strakes are pear wood. In the opening for the main deckhouse, the top of one mounting bolt can be seen. It is secured to a heavy brass plate inside the model. (Image by Rob Napier)