[nggallery id=41]

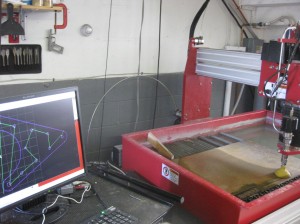

All hardware for the masts is being cut by a computer driven high pressure water jet cutter. In photo 1 a test piece is being cut. The computer screen shows Greg's drawing in purple. The green line shows the route that the machine will take to pre-cut the holes. In picture 3 Tom quickly polishes the cut edges. In picture 4 Martin and Sid are hard at work custom bending the bronze tangs to the shape of the mast. Note, the hydraulic press and the energy drink. Photo 5 is a nice shot of some of the completed bronze spreader link plates. Photo 6 shows the original hardware which is being compared to Greg's new drawings. The bronze plate sizing varies up and down the mast from less than 1/8th of inch to 3/16th's of an inch thick. All hardware has been cut from Phosphor Bronze plating. Each component takes roughly four minutes for the computer to drill and cut.